Bioquell Qube for Healthcare

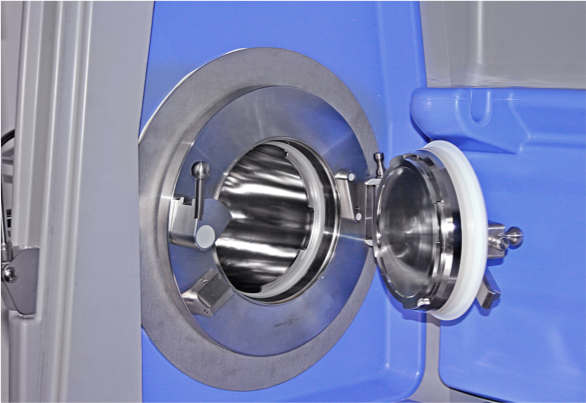

You can create a secure aseptic processing workspace to prepare individual patient prescriptions while meeting the latest regulations, and protecting your patients and staff with the Bioquell Qube. This configurable isolator comes integrated with Bioquell’s Hydrogen Peroxide Vapour technology.

Ideal for:

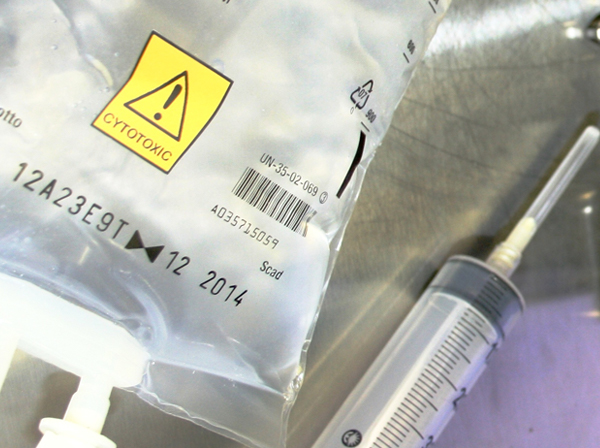

- Compounding sterile and non-sterile drugs

- Hazardous Drug (HD) compounding

- Cytotoxic drug preparation

WHY CHOOSE THE Bioquell Qube for Healthcare

Rapid

Decontamination cycles in as little as 20 minutes for rapid so you can increase prescription throughput

Adaptable

Work in negative or positive pressure; Modular workspace to meet your needs from two to six gloves

Assured

Creates an ISO 5/EU Grade A cleanroom environment in your pharmacy while residing in a lower grade space

Accepted

Meets or exceeds global regulatory compliance standards including USP 797 and USP 800

Integrated

Built-in Bioquell Hydrogen Peroxide Vapor technology for reliable, repeatable decontamination results; easy-to-use touch-screen controls

Productive

Installed with no construction needed; requires a single outlet for power; no ductwork required; ready for use as soon as 12 weeks from order date

APPLICABLE SOLUTIONS

Modular and Expandable Configurations

The Bioquell Qube offers multiple configuration options ranging from one to three chambers with up to two optional exterior/material transfers. Add chambers or material transfers as your needs change.

ACCESSORIES

Environmental Monitoring

Fully integrated, pre-engineered options for total particulate and viable monitoring systems to help meet regulatory reporting requirements

Fully integrated, pre-engineered options for total particulate and viable monitoring systems to help meet regulatory reporting requirements

Options for optimizing each chamber: full-size option for maximum storage of vials, delivery devices, reagents and other materials during decontamination cycles

Contact us for more information about accessories in the Bioquell qube to help optimize your workflow.

Contact UsInstallation, Validation and Compliance

Our technical experts can install and validate the Bioquell Qube in as quickly as two weeks in most instances. Because the Bioquell Qube is easy to maneuver and fast to assemble, you often do not need any construction or electrical alterations to install. It can fit through 800mm (32-inch) door frames to be built directly in the designated area, and it requires only a standard electrical outlet to function.

Validation includes training, installation, operational and performance qualification (IQ, OQ and PQ), validated cycles based on custom-load configurations, and all appropriate documentation.

Preparation of sterile drugs and Hazardous Drug compounding continue to experience increased regulatory control around the world. The Bioquell Qube provides assurance that requirement are being met. Protect your staff, your patients, your prescriptions and your facility by using the Bioquell Qube and Hydrogen Peroxide Vapor technology.

FAQs

Will this offer 21-CFR Part 11 compliance?

Yes, we are able to offer an optional data logger for this purpose.

What is the internal floor of the Bioquell Qube made from?

The floor of the Bioquell Qube is constructed from 316 stainless steel to ensure resistance to scratching on the working surface.

I have a small sterility-test need right now. What happens when my needs change?

The Bioquell Qube allows you to add and expand the system as your testing needs change and grow.

How can I bring tubing or cables into the Bioquell Qube?

We have an option for fitting a floor-mounted one-inch triclover port in each chamber. This allows you to bring in liquid lines or cables securely into the body of the Bioquell Qube.

What sets the Bioquell Qube apart from traditional stainless steel options?

The Bioquell Qube is constructed of tough and hard-wearing polypropylene, which is resistant to most materials the unit is ever likely to come into contact with. Because of its construction, the Bioquell Qube can be installed and validated within 12 weeks and, in most cases with minimal invasiveness to your operation or workflow.

Can you set alarms for the temperature inside the Bioquell Qube?

Yes.

If I wish to change pressure from positive to negative, do I need to change the filters or take any additional action to ensure it is safe to use?

The Bioquell Qube can be switched between pressure regimes simply with the touch screen; no additional changes are needed.

Are there different leak tests programmed for the Bioquell Qube?

Yes, there are leak tests programmed for both positive and negative pressure.

Contact Us

To learn more about how Bioquell can fit your solution, please contact us.

The Americas

Bioquell Inc.

702 Electronic Dr. Suite 200

Horsham, PA 19044

+1 215 682 0225

[email protected]